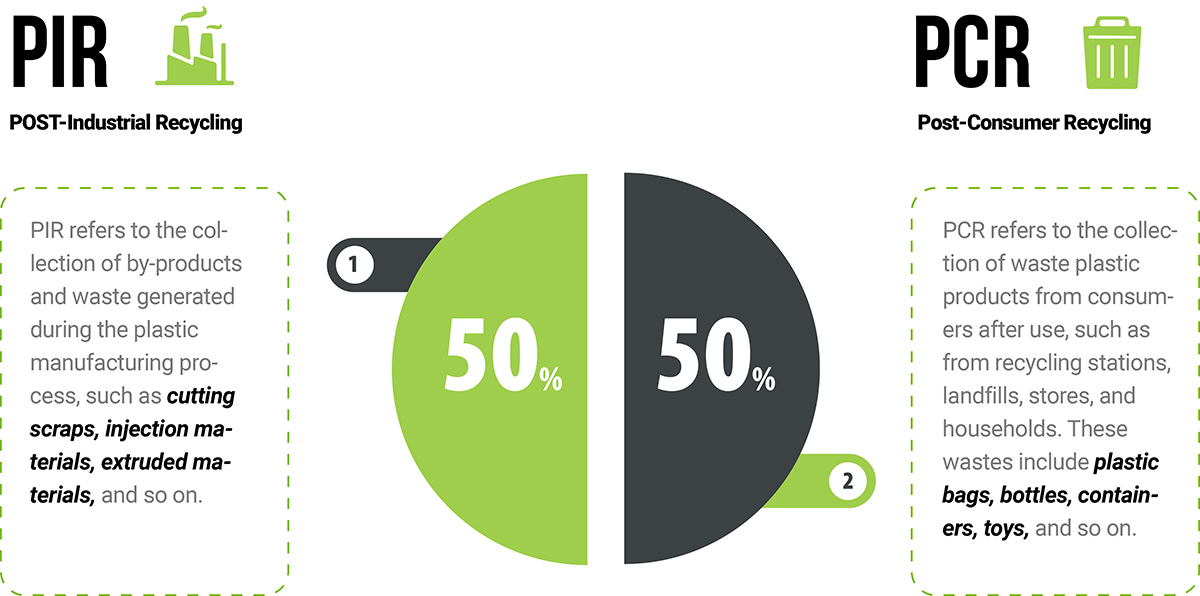

2 ways of recycling

HETRON's Environmental Commitment from Material Preparation to Recycling

Exploring Two Recycling Methods in the Market

PIR is often overlooked

HETRON's Path to Sustainability, Cost Reduction, Superior Material Quality, and Enhanced Efficiency

1. High Reprocessing Quality

High Reprocessing Quality: Post-Industrial Recycled (PIR) materials originate from water sprues, off-spec products, and defects generated during factory injection molding. These materials typically maintain high processing quality during recycling, resulting in superior quality for reprocessed products.

2.Significant Environmental Impact

The recycling of PIR materials can significantly reduce industrial waste emissions and mitigate environmental pollution. By enabling recycling and reuse, the demand for virgin plastics decreases, leading to reduced carbon dioxide emissions and energy consumption, thus contributing to the achievement of carbon neutrality goals.

PIR is often overlooked

HETRON's Path to Sustainability, Cost Reduction, Superior Material Quality, and Enhanced Efficiency

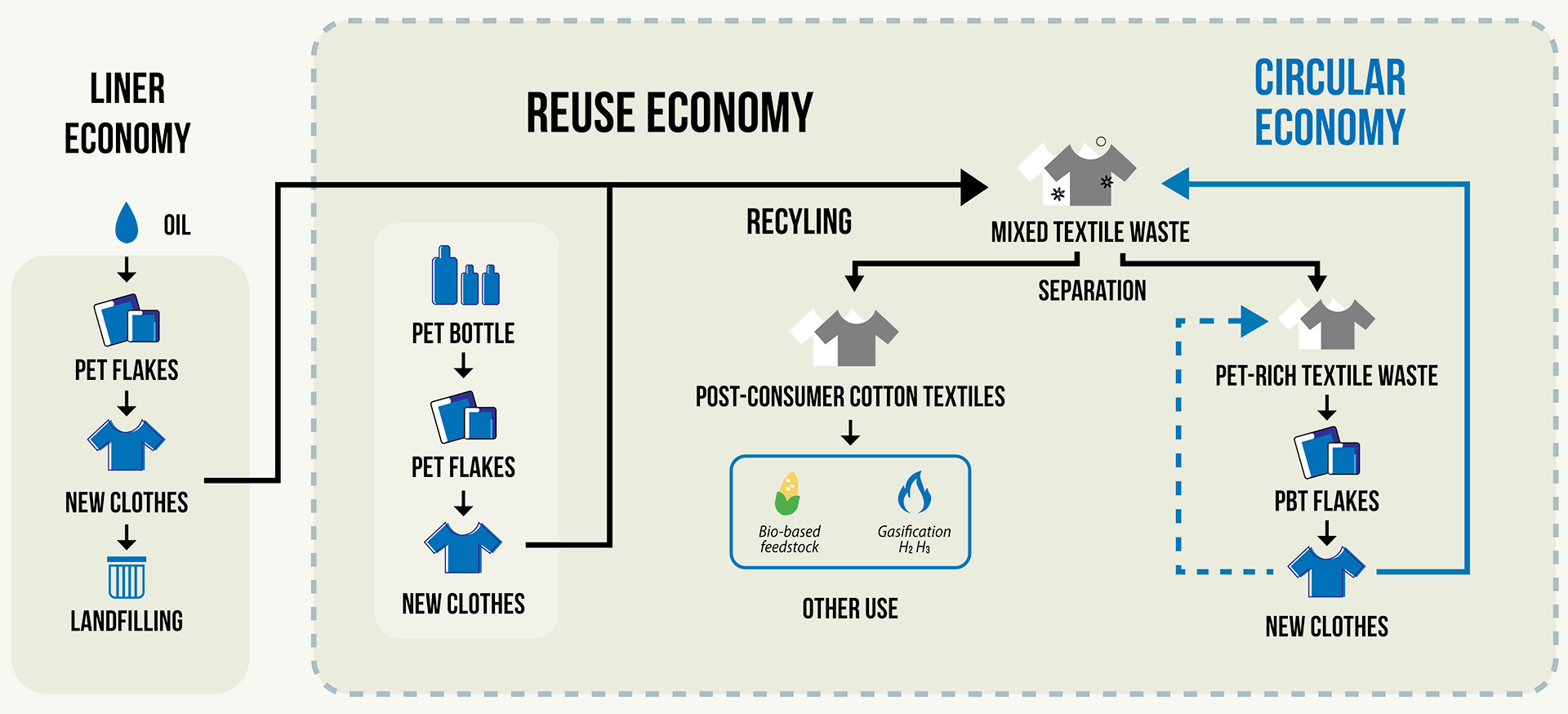

We employ a chemical recycling method to process recycled polyethylene terephthalate (rPET), beginning with the extraction of recycled terephthalic acid (rPTA) from rPET. Next, rPTA is reacted with 1,4-butanediol (BDO) to synthesize recycled polybutylene terephthalate (rPBT). Finally, rPBT is polymerized with polytetramethylene glycol (PTMEG) to produce recycled thermoplastic elastomer (rTPEE).

the Principles of rPET Chemical Recycling

—————— Transforming Waste into Valuable Resources

The principle of chemically recycling rPET involves converting discarded polyethylene terephthalate (PET) bottles into high-value raw materials for the production of polyethylene terephthalate (PET). This process is achieved through the following steps:

Pyrolysis: Waste PET bottles are heated to high temperatures, causing them to decompose into monomers such as terephthalic acid and ethylene glycol. This process effectively breaks down the polymer structure of PET, releasing the original monomers.

Chemical Reaction: The extracted terephthalic acid and ethylene glycol are then reacted through esterification or polymerization to synthesize new polyethylene terephthalate. This method not only allows for the sustainable utilization of waste but also reduces dependency on virgin raw materials and lessens environmental pressure, promoting the recycling of resources.

Chemical recycling in textile reuse enables a closed-loop system, transforming post-consumer textiles back into high-quality raw materials for new textile production.

Advantages of Chemical Recycling of rPET

Unlike traditional physical recycling methods, chemical recycling does not degrade the quality of polyester raw materials, thereby expanding the range of applications. This method can convert discarded PET bottles into high-quality polyester raw materials, with performance and application areas comparable to that of virgin PET. Moreover, chemical recycling reduces dependence on raw materials, lowers environmental pressure, and promotes the development of a circular economy.